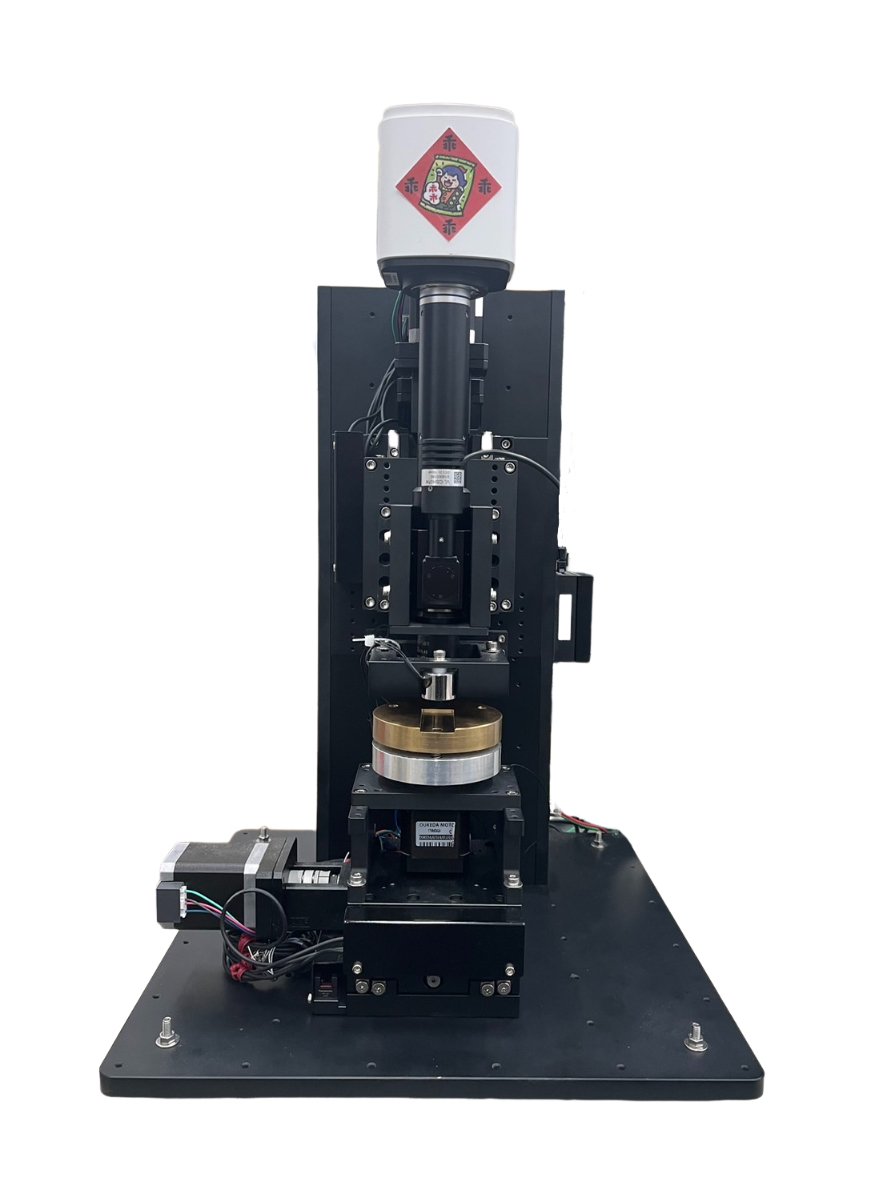

High-Precision Stacking Alignment Machine

Recently, two-dimensional (2D) materials, including graphene, transition metal dichalcogenides (TMDs), and transition metal oxides, have attracted much attention in research and applications. These 2D materials signify their features of easy exfoliation due to van der Waals stacking between layers. Therefore, it is possible to pick up different 2D layers and stack them together to make heterostructures as new functional materials. However, placing 2D materials precisely on any specific positions atop the sample substrate is difficult. Here, we provide an automatic system, equipped with a high-resolution CCD, high spatial resolution XYZ motors, a PID-controlled heater, programmable RGB contrast analyses, and smart software for friendly human-machine interfaces. We plan to offer excellent and easy-stacking experiences without limitation for researchers and engineers.

Precise Alignment

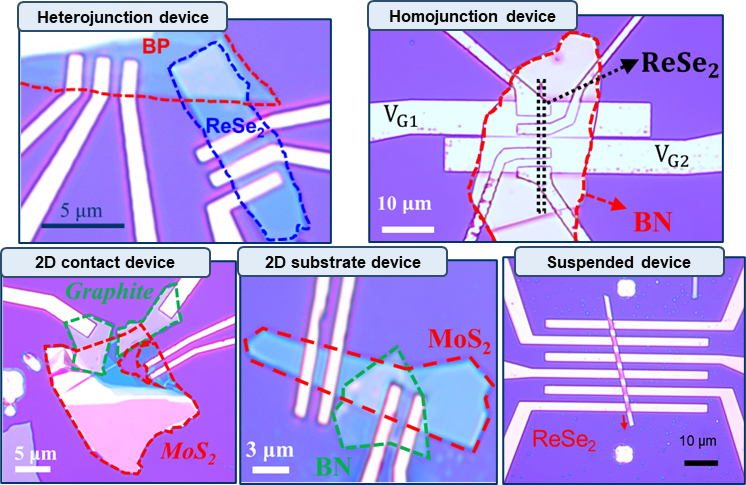

Through multiple high-resolution motors, the 2D material flakes can be oriented and moved to place on top of either pre-patterned metal electrodes or another 2D flake at the substrate. In particular, the system offers a high resolution in rotation thus a magic angle of layer-by-layer stacking is achievable. The system has been tested for years and upgraded several times to present its optimum performance in the state-of-art fabrication method. This new system provides diverse possibility for making devices, such as p-n diodes, suspended 2D material devices, photodetectors, and solar cells. According to the database of RGB contrast, the thickness of 2D material films can be determined. In particular, this system quickly help to stack 2D materials on your substrates so as to significantly decrease air exposure time and avoid oxidation and deterioation. The damage from lithography process can be prevented if the 2D material films are attached after the metal electrodes are prepared. This system offers various functions of manufacturing for you to design new device structures.

Through multiple high-resolution motors, the 2D material flakes can be oriented and moved to place on top of either pre-patterned metal electrodes or another 2D flake at the substrate. In particular, the system offers a high resolution in rotation thus a magic angle of layer-by-layer stacking is achievable. The system has been tested for years and upgraded several times to present its optimum performance in the state-of-art fabrication method. This new system provides diverse possibility for making devices, such as p-n diodes, suspended 2D material devices, photodetectors, and solar cells. According to the database of RGB contrast, the thickness of 2D material films can be determined. In particular, this system quickly help to stack 2D materials on your substrates so as to significantly decrease air exposure time and avoid oxidation and deterioation. The damage from lithography process can be prevented if the 2D material films are attached after the metal electrodes are prepared. This system offers various functions of manufacturing for you to design new device structures.

Specifications

| Profiles in Detail | |

| Length – Width – Height (working) | 350 – 350 – 650 (mm) |

| Power | 110C AC Power |

| Moving Stage – X, Y, Z1, Z2 | moving range up to 70 mm, resolution up to 0.1 micron |

| CCD | X1000 magnification, 1920 X 1080 |

| Sample Holder | Magnetic Attachment |

| Heater | RT up to 150oC |

| Rotational Resolution | ~0.1o |

| Operation System | Windows 10 later version |

| Connecting Ports | 2 USB ports |